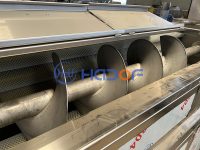

This potato chips production line consists of lifting feeder — roller cleaning stone removal machine — lifting machine — brush peeling machine — manual selection conveyor belt — quantitative lifting feeder — slicing machine — air bubble cleaning machine — air blown stranding machine – rotary type continuous frying machine – lifting selection conveyor — vibration feeder – roller mixing machine — finished product conveyor –420 type automatic packaging machine — air pressure Mechanism nitrogen machine – metal detector – sealing machine.

Proceso de trabajo

1.Potato Washing and Peeling: The process begins with the cleaning and peeling of the raw potatoes. Con la ayuda de la máquina de eliminación de piedras de limpieza de rodillos y la máquina peladora de cepillos, Esta etapa puede eliminar la suciedad, Impurezas, y la piel exterior de las patatas.

2.Potato Slicing: The peeled potatoes are sliced into thin, uniform slices by the slicing machine. Consistency in thickness is important to ensure even frying and consistent product quality. Our slicer has the features of smooth surface, fast cutting, easy cleaning and simple operation, which can save manpower and cost.

3.Limpieza de burbujas de aire: El tiempo de limpieza es de 30-40S. Durante el proceso de limpieza, the starch and sugar on the surface of potato chips can be removed to prevent the deterioration of the oil body and prolong the service life of the oil.

4.Blanqueo: El escaldado es un procedimiento necesario. Put the potato slices into the blanching machine with a water temperature of about 65-90℃, que puede destruir la actividad enzimática, Mejorar y suavizar la estructura del tejido, make it easy to dry, and also prevent frying and foaming.

5.Secado: Drying the moisture on the surface of the potato chips can effectively reduce the oil content of the potato chips during frying, improve the taste of the potato chips, y reducir el consumo de energía de la fritura.

6.Fritura: El tiempo de fritura es 2-3 minutos y la temperatura de fritura es de 170-180 °C. The dried potato slices are deep-fried in oil at controlled temperatures until they become crispy and golden brown.

7.Seasoning: Después de freír, the chips can be seasoned with various flavors such as salt, spices, or other flavorings. This can be achieved through a seasoning drum machine.

8.Embalaje: The final step is to package the potato chips into bags, Bolsas, o contenedores. 420 La maquinaria de envasado automática garantiza un sellado y una protección adecuados del producto para mantener la frescura y prolongar la vida útil.

Máquinas de procesamiento de alimentos HADOF, horno de secado para la venta

Máquinas de procesamiento de alimentos HADOF, horno de secado para la venta

×

×

Hello sir, I need a natural potato production line with a production capacity of 300 tons per hour with all the details and it must be fully automatic. We are thankful for your cooperation with us. I am Bakil Soufan, the correspondence officer for the Yemeni Food Industries Company.

For my cassava processing business, I want to know the price of cassava peeler, machine, cassava splicing machine and cassava dryer machine.

Dear

My nees 100 kg daily autio production patoto chips line matchin, pls cost estimate & machine Detail

Sayedmasud.bd@gmail.com

Dear

My needs 100 kg daily auto production Natural patoto chips line matchin, pls cost estimate & machine Detail

Sayedmasud.bd@gmail.com

Ok

Good morning, l am looking for a extruder to manufacture puff an corn products.

Bonjour

Nous cherchons dès lignes de production de frites et outre légumes.

Merci de nous répondre rapidement merci

Please furnish me with the price of whole chips making machinery including packaging in poly bags of various sizez

How can I get the product

Hi.i plan to buy this production line and export to oman.i am interested to know how much cost this production line. Thanks

beef meat dumpling production

Hello together,

i need a production line for french fries complete.

can make me a Offre EX Works to Tunesia port Tunis.

the Heating should be with Gas.

the Capacity should Min 100kg/h to more.

Best Regards

Ahmed Hachem

Nice and wonderful

Last price please

Would love to use you product to create my brand

I need the complete process machines for making potatoes, plantain and other chips machines.

Moderate prices please.

Thanks

Very impressed. Can I have catalogue if you have any with details of the line such as dimensions. Also, if you can show the maximum area the line can occupy. Thank you in advance.

I want to know how much the machine cost . I want to open chips company in Africa.

Please send me your price for the potatoes processing machine